New Type Full automatic pp nonwoven SMMS SMS Non Woven Fabric

Production Line

How to develop non-woven manufacturing business?

If you want to buy nonwovens, all potential buyers should check the

following factors:

1. Sufficient project investment. This nonwovens machine costs

$200000 to $5 million.

2. The workshop space is 200-500 m2 of non-woven machine, with a

space length of 30 meters, a width of - 20 meters and a height of

11 meters.

3. Non woven machine operation team 4 - 6 persons

4. Polypropylene raw materials and additives 5 tons per day

5. Stable power supply system 380 or corresponding

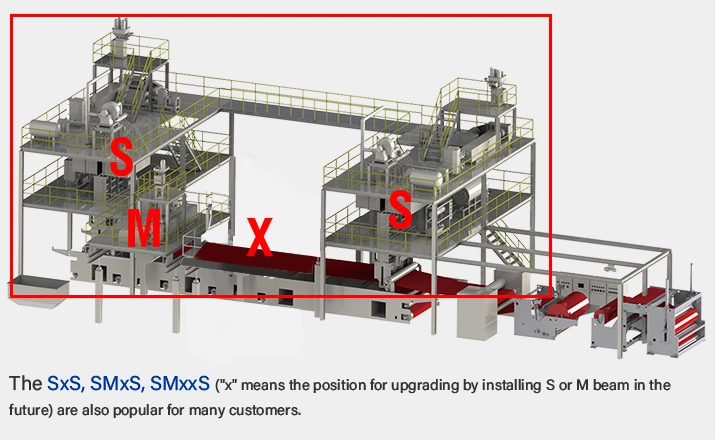

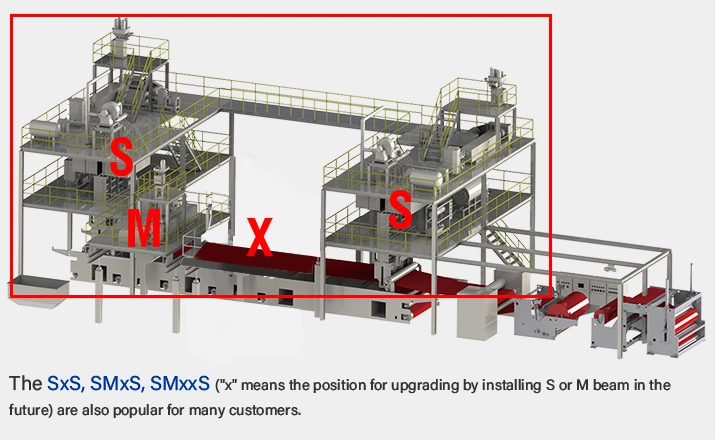

SXS smxs smxxs (x refers to the location where s or m beams will be

installed for upgrading in the future) is also welcomed by many

customers.

HHM non-woven production line is designed and manufactured flexibly

according to the individual requirements of customers. Our possible

application fields are also wide.

Nonwoven system parts

1. Automatic air suction device: 1 set

2. Polymer extrusion and melt blown spinning system

(1) Screw extruder

Model: φ ninety

Screw technical parameters:

Diameter: 90 mm

Material: 38 crmoala

Surface treatment: Nitriding polishing

(2) Filtration equipment

Driving type: Hydraulic

Structure: plate type double station hydraulic screen changing

device

Pressure sensors: input configuration

(3) Metering pump

Extrusion output: 50 - 120kg / h

Pressure sensor: input and output can be configured

Driving power: 4.5kw

(4) Melt conveying pipeline and thermal insulation material

(5) Combination of melt blown die and spinneret

Mold material: sus630

Die size: 1600 mm

Spinneret material: sus630

Opening length of spinneret: 1700mm

Spinning hole diameter: ≤ 0.25mm-0.35mm (customizable)

Length diameter ratio of spinning hole: 14:1

3. Receiving network system

(1) Receiving networking devices:

Linear speed: up to 50m / min

Adjustment range of melt blown material receiving: 200mm

Installation form: it can be moved horizontally to facilitate

installation, commissioning and maintenance

Driving speed: 1.1 kw

(2) Exhaust fan:

Power: 75 kW,

4. Hot air heating system

(1) Atlas air compressor

Boost: 0.7 MPa

Power: 120 kW ~ 200 kw

(2) Air heater

Heating power: 220 kW - 240 kw

Tank and pipeline material: stainless steel 304

Insulation form: stainless steel sealing is adopted outside the

insulation layer

5. Electret system.

6. Platform equipment:

Steel structure, easy disassembly, firm and reliable, including

stairs, etc.

7. Heating power of die head: about 70kw

8. Electrical control box

| Machine Model | Reifenhauser Reicofil 3/4,Spunbond lines, spun-melt lins S, SS,SSS,

SXS,SXXS,SMMS ,SMS ,SSMMS |

| Machine Size | 18m-60m(L)*10m-31m(W)*10m-12m(H) |

| Raw Material required | PP(polypropylene),additives MFI/MFR:25-40g/10min(spunbonding process) MFI/MFR:800-2000g/10min (Melt-blowning process) |

| Effective width | 1600mm,2400mm,3200mm,4000mm,4800mm customizable width by

requirements |

| Max Speed | 150m/mn-550m/min |

| Transformer&Power consumption | Transformer require:200KVA-3000KVA Power consumption :500KWH/Ton-1400KWH/Ton |

| Output per year | 1500 Tons - 10000 Tons |

| Products GSM | 8gsm-250 gsm |

| Applications of products | Industrial:Shopping bags, furniture ,agriculture ,packageing,etc Medical:Surgical gown /cap /sheet /mask ,etc Hygiene: Diapers ,sanitary ,napking , etc. |

Such as :

PACKAG - Shopping bag, Rice Packaging, Clothes packaging, etc.

HYGIENE - Baby and adult diapers, Female hygiene, etc.

MEDICAL - Surgeon's masks, Disposable garments, etc.

FURNITURE - Beds Cover, Seatings Cover, etc.

TECHNICAL - Geotextiles, Agriculture, etc.

FILTRATION - Air, Gas, Liquids, etc

4800 SMMS Model

| Effective Width | 4000mm |

| Weight Range | 9 - 100 g / ㎡ |

| Out put daily | 23 - 36 ton |

| Machine speed | ≦ 450 m / min |

| Transformer | ≈ 2000 + 630 KVA |

| Power Consumption | 1700º - 1900 º / Ton |

| Machine Size | 55 *31* 12 M |

HHM SMMS Product application

| Material | PP chip | Weight range | 10-150 g/m2 |

| Model | HHM-1.6SMMS/HHM-2.4SMMS HHM-3.2SMMS/HHM-4.0SMMS/HHM-4.8SMMS | Fabric usage | Medical applicant,shopping bag , packing Operation suit,face mask, baby diaper.etc |

HHM SMMS Non woven fabric making catalog

| Effective width(mm) | 1600 | 2400 | 3200 | 4000 | 4800 |

| Output(ton/year) | 4000T | 6200T | 5400T | 10500T | 12700T |

| GMS Range(g/㎡) | 9-100 | 9-100 | 9-100 | 9-100 | 9-100 |

| Max.speed(m/min) | 450 | 450 | 450 | 450 | 450 |

SMS Model

| Effective width(mm) | 1600 | 2400 | 3200 | 4000 | 4800 |

| Output(ton/year) | 3200T | 5100T | 7000T | 8700T | 10500T |

| GMS Range(g/㎡) | 9-100 | 9-100 | 9-100 | 9-100 | 9-100 |

| Max.speed(m/min) | 350 | 350 | 350 | 350 | 350 |

SMMS

| Effective width(mm) | 1600 | 2400 | 3200 | 4000 | 4800 |

| Output(ton/year) | 4000T | 6200T | 5400T | 10500T | 12700T |

| GMS Range(g/㎡) | 9-100 | 9-100 | 9-100 | 9-100 | 9-100 |

| Max.speed(m/min) | 450 | 450 | 450 | 450 | 450 |

SSMMS

| Effective width(mm) | 1600 | 2400 | 3200 | 4200 | 4800 |

| Output(ton/year) | 6200T | 8000T | 11000T | 14000T | 16000T |

| GMS Range(g/㎡) | 9-80 | 9-100 | 9-100 | 9-100 | 9-100 |

| Max.speed(m/min) | 600 | 600 | 600 | 600 | 600 |

Image of non woven fabric making system

Parts of spunbonded nonwoven fabric production line:

Recycle extrude→Main extruder→Filter→Metering pump→Monomer suction

device→spinning box( Changzhou/ENKA/KASEN spinneret )→Quenching air

chamber→stretching device→Web former→Calender→Winder→Slitter

Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)→Raw

material→Melting→Filtering→Measuring→Spinning→Cooling→Stretching→Web

forming→Calendering→Winding→Cutting→Final product

Parts of Melt blown nonwoven fabric production line:

Main extruder→filter→Metering pump→Air heating system→Melt blown

sprayer (ENKA sprayer)→Web former→Winder→Slitter

Melt blown process and technical flow chart:

Raw material →Melting→Filtering→Measureing→Air heating→Spraying→Web

forming→Winding→Cutting→Final product

working process chart

Main parts of SMMS non woven fabric making line

Melting Filter Also known as a quantitative pump or proportional

pump, it is a reciprocating pump that can adjust the flow rate, and

its flow can be adjusted stepless in the range of 0-100%. The

characteristic is that the discharge pressure can be kept constant

when the flow is adjusted. A device used to measure the amount of

PP melts.

Spinning beam One of the main components of the melt spinning

machine is a polymer melt through the filter into the spinning box

and spinning through the melt distribution and heat preservation. A

rectangular metal box with a box for outsourced insulation. It

contains the melt distribution

Upper Stretching Device Make the tow tensioned."

Lower Stretching Device Make the tow even more uniform before

entering the netting mach

the electric control cabinet to electric power distribution and

control equipment power."

Vacuum calcinator

The latest chemical fiber component, filter core cleaning

equipment. It is suitable for the ordinary spinneret used for

polyester, polyamide and polypropylene fiber."

Two cooling blower for each other pressure gauges, pressure

switches, air channel transfer baffles, air oil and water filter

separators, cooling fan control cabinet and so on. Two cooling fans

share a control cabinet to automatically control the start and stop

of the two typhoon machines. The cooling wind can be taken directly

from the air or from the outlet of the fan.

Suction blower is used to pump, exhaust gas, and to compress the

gas, and convert the energy input into the kinetic energy and

potential energy of the gas in order to increase the unit energy of

the gas.

High - precision CNC tools make sure machining part beyond customer

request

Exihibition Show with customer

packing and delivery

| Loading Details |

| Container | 4-12 Pcs of 40HQ Container |

| Port | Nanjing or Shanghai Port |

Packing Details | The normal package is wooden Cases.

Some of huge equipment will load with wooden case;.

Each container weight 20-25 Tons. |

FAQ

1.Q:I already have one factory but there is a little difference in

the size,for example the height can't meet 13m,only 12m?

A:Don't be worry. Your machine could be customized.

2.Q:How to make sure your machine's quality?how about the service?

A:Each machine gets ISO9001:2008,CE, SGS. And warranty is one year.

you can enjoy the service within production lifetime.

3.Q:How can I get right machine for myself, if I have no ideal

about it?

A:Tell me what kind of fabric that you want, how much you want to

produce and your factory szie etc. We will design for you.