S Model (Packaging , Agricultural Cover )

| Working width | Fabric | Consumption | Annual output/Year |

| 1600mm | 9-250G/㎡ | 130KW | 1800T |

| 2400mm | 9-250G/㎡ | 180KW | 2200T |

| 3200mm | 9-250G/㎡ | 200KW | 3300T |

| 4000mm | 9-250G/㎡ | 300KW | 4400T |

| 4800mm | 9-250G/㎡ | 400KW | 5100T |

SS Model ( Baby Diaper ,Medical Products )

| Working width | Fabric | Consumption | Annual output/Year |

| 1600mm | 9-120G/㎡ | 200KW | 3700T |

| 2400mm | 9-120G/㎡ | 2500KW | 5100T |

| 3200mm | 9-120G/㎡ | 200KW | 6600T |

| 4000mm | 9-120G/㎡ | 300KW | 8800T |

| 4800mm | 9-120G/㎡ | 450KW | 10000T |

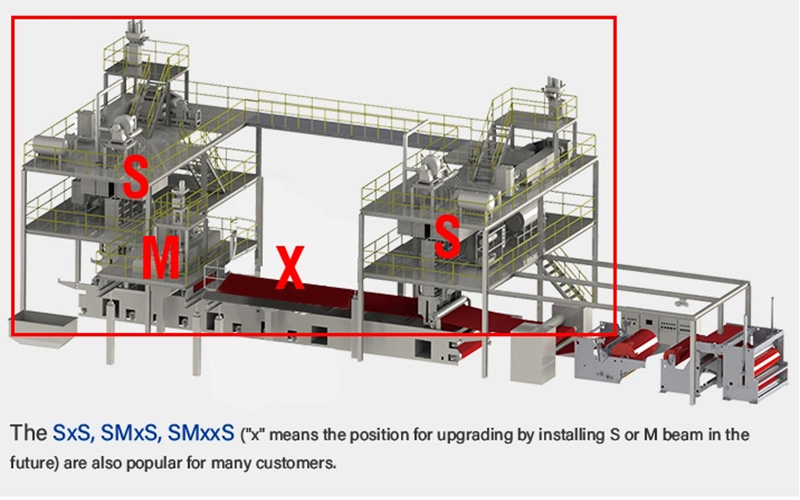

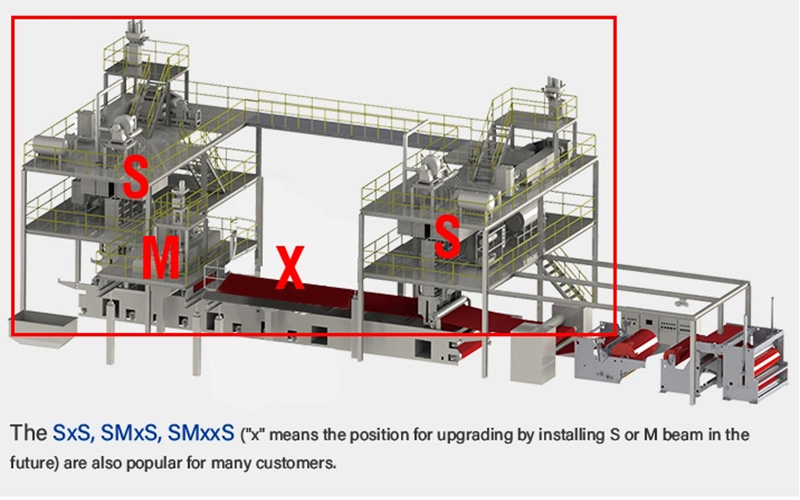

SMS/SMMS/SSMS/SSMMS Model(Filtration Material, Baby Diaper ,Medical

Products)

| Working width | Fabric | Consumption | Annual output/Year |

| 1600mm | 15-250G/㎡ | 400KW | 3200T |

| 2400mm | 15-250G/㎡ | 600KW | 5100T |

| 3200mm | 15-250G/㎡ | 800KW | 7000T |

| 4000mm | 15-250G/㎡ | 1000KW | 8700T |

| 4800mm | 15-250G/㎡ | 1200KW | 10500T |

Parts of spunbonded nonwoven fabric production line:

Recycle extrude→Main extruder→Filter→Metering pump→Monomer suction

device→spinning box( Changzhou/ENKA/KASEN spinneret )→Quenching air

chamber→stretching device→Web former→Calender→Winder→Slitter

Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)→Raw

material→Melting→Filtering→Measuring→Spinning→Cooling→Stretching→Web

forming→Calendering→Winding→Cutting→Final product

Parts of Melt blown nonwoven fabric production line:

Main extruder→filter→Metering pump→Air heating system→Melt blown

sprayer (ENKA sprayer)→Web former→Winder→Slitter

Melt blown process and technical flow chart:

Raw material →Melting→Filtering→Measureing→Air heating→Spraying→Web

forming→Winding→Cutting→Final product

Core component of non wovne system

Meltblown die head assembly

maximum temperature: 300.;

Max.output:200kg/h;

Heating zone:8tod;

Perforated length:3,350mm;

HPI:40;

1 Sets L/D=10; Number of holes:5.276;

Capillary diameter:0.3mm;

Capillary length:3,600mm;

Oil Heating Furnace

The heat-conducting oil furnace is mainly used for heating,

melting, spinning, thermosetting polymerization, finishing of

fabric, extension and drying equipment. The working temperature can

be controlled accurately

Name: Material Auto-Feeder

Feeding capacity: 300Kg/h for 3.2m,

Motor Power: 1.1KW

The vacuum suction machine forms a negative pressure air flow under

vacuum. Under the action of this airflow, the transported material

is transported to the other container through the suction pipeline

instantaneously. As a result of the vacuum condition, the material

will not leak into the surrounding environment and prevent dust

pollution even if the pipe leakage occurs. It is a device used to

adsorb raw materials.

Extrusion Machine

Aperture:90 300kg/h 1pc;

Heating System: electricity heating; Drive Motor: Siemens;

Original:CHINA;

Spinneret

The role of spinneret is to transform viscous flow of polymer melt

or solution into small section with special section, and solidify

through solidified medium, such as air or solidification bath. It

is used for the uniform exit of the tow.

Vacuum calcinator

The latest chemical fiber component, filter core cleaning

equipment. It is suitable for the ordinary spinneret used for

polyester, polyamide and polypropylene fiber."

up stretching

The stretching device including up stretching and down stretching

unit, the function is drawing spinning, flaments into web forming

by air.

lower strenting

Make the tow even more uniform before entering the netting machine

Web forming machine , Its function is to use negative pressure to

collect fiber and continuously carry forward, so as to obtain

continuous fiber network. The device is composed of a direct

current transmission device and a frame, a transmission net curtain

and a supporting air suction device. It belongs to the tow mobile

device.

Automatic Winding Machine

Effective width:1600/2400/3200 mm Rolling Speed:200-400M/Minute

Rolling Diameter:2000 mm Original: CHINA

Automatic Slitting Machine

Speed:600-800 M/Minute; Min. Slitting width:80mm; Max. Rolling

size:1500mm diameter; Auto tensile control:online; Auto meter

counting:online; Original:CHINA;

High precisely CNC center hold machining parts beyond customer

request

Exhibition with customer

Shipping and packaging

Main machine parts will be packed with wooden cases.Electrical

parts will be packed with plastic and then packed into wooden

cases.For the steel structure they will be packed in bulk into

containers

How to start the Nonwoven fabric manufacturing business ?

All potential buyers should check below factors if you want to

produce nonwoven fabrics .

- Enough project investment : This nonwoven fabric machine cost

$200000 to $5000000 Ave.

- Workshop space for nonwoven fabric machine 200 -500 ㎡,space length

30 meter , width 10 -20 meter , height 11 meter

- Nonwoven fabric machine operation team 4 - 6 workers

- Polypropylene raw material and additives 5 tons each day .

- Stable electricity supply system 380 V.

FAQ

Q1: What's your warranty policy?

A1: The Seller will guarantee the machine for 18 months since the

date of shipment (that is leaving from Seller's factory) or the

seller will guarantee the machine for 12 months since the date of

starting installation and adjustment, whichever comes first.

Q2: What's your minimum order quantity?

A2: Min order quantity: 1 set or by negotiate with each other.

Q3: What package do you use for the product?

A3: Be Coated with anti-corrosion oil, and covered with plastic

film, then packed in wooden box.

Q4: Do you have technical instruction if I buy your product?

A4: Please read the user manual carefully for your reference, we

have detail instruction on it. If your problems still cannot be

solved, welcome to contact us for help.

Q5: What is your overseas service?

A5: We will provide high quality overseas service, our technical

staff will be able to provide you with technical support, for you

personally to overseas assembly and test equipment.

Q6: Will you conduct training for our staff here?

A6: Yes, we will provide technology support to factory technology,

training for the relative person.

Q7: What are your terms of payment?

A7: We accept T/T.

Q8: How does your factory do regarding quality control?

A8: Quality is priority. We always attach great importance to

quality controlling from the beginning. And we have CE certificate.

Q9: How does your factory control the quality?

A9: We have the professional QC group inspect the details in each

process. After finishing the goods, our QC will inspect piece by

piece.

Q10: I am very satisfied after I read your FAQ, how can I start to

purchase my order?

A10: Please click the "send" at the bottom of this page or contact

our sales on Trade Mange online!

Dear friend:

Welcome you purchase our standard products or send us your OEM and

ODM requests. You will be impressed by our superior quality, quick

delivery date and attractive price. If any question about non-woven

machine, contact me at any time, please!