Full automatic High Capacity 1600 2400 3200 SMS SMMS PP Spunbond

Nonwoven production line

HH non-woven series spunbond, melt-blown complete set of non-woven

cloth machine, combing installation, commissioning and after-sales

service. On the basis of continuous innovation and improvement, we

can make full use of new technologies and new materials to ensure

the stability and reliability of products and constantly meet

customer requirements.

Our non-woven fabric manufacturing machine can produce different

10-250GSM high quality spunbond non-woven fabric.

The spinning die head adopts the coat hanger flow model to optimize

the design, the melt distribution is uniform, the pressure is

balanced, the fiber does not break or combine, there is no hole, no

dead Angle, the color transition is fast. The mill adopts dc motor

universal joint drive; The roller adopts super laser drilling

technology to ensure the same temperature and no burrs during

filling. The equipment uses in-line cutting, automatic low winding

technology to service resources and improve production efficiency.

Feature Definition:

1. Softness and stiffness. Precision, scalability.

2. Filter, breathable and waterproof. Flexibility, rigidity.

Thin as cicadas and thick as felt. Water is permeable to moisture

4. Filling resistance, wrinkle resistance, good elasticity, high

moisture absorption, waterproof.

Spunbond nonwovens: polymers extruded, stretched, formed continuous

filament, filament laid into a network, fiber network by

self-bonding, thermal bonding, chemical bonding or mechanical

bonding. A method of making a fiber net into a nonwoven fabric.

Features: good performance (can be used in 150℃ environment for a

long time, polyester can be used in 260℃ environment for a long

time), aging resistance,. Uv, high elongation, good stability and

permeability, corrosion resistance, sound insulation

Important data at a glance

Voltage | AC380V,50 Hz |

GSM RANGE | 10-100GSM |

MAX SPEED | 500m/min |

PRODUCTION CAPACITY | 5000ton/year |

Material | Polypropylene chips (meltblown PP MIF: 1500-1800; Spunbond PP MIF:

28-45) |

Product Width | 1600mm:10-100gsm |

Max. Roll Diameter | 1500mm |

Power Consumption | ≥800kw |

Air pressure | 0.5-0.8MPa |

Cooling water | 5m2/h,20℃ or 2.5m2/h,10℃ |

Equipment Size | 35m(L)X 18m(W)X 12m(H) |

| Spunmelt Composite Nonwovens Mainly Applications |

| Nonwoven Medical Product | Surgical drapes ,Surgeon’s mask ,etc . |

| Nonwoven Hygiene Product | Baby and adult diapers |

| Work protection product | Protctive clothing , breathing masks |

| Nonwoven Filtration product | Protective clothing , breathing masks |

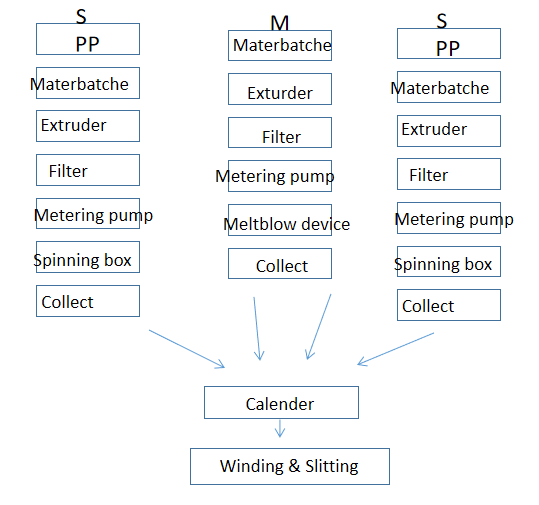

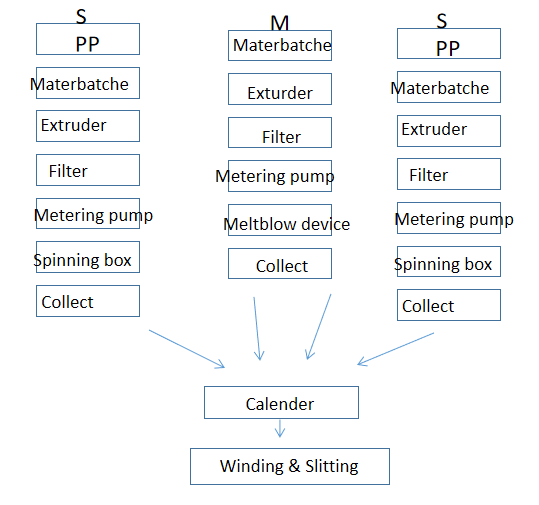

working process

1. PREPARE OF RAW MATERIAL

2. LOADING MATERIAL TO HOPPER/DOSING SYSTEM

3. SCREW EXTRUDER FOR MELTING MATERIAL

4. MELTING FILTERIMPURITY; METERING ACCRODING FINISHED WEIGHT

5. SPUNBOND: SPINNING BOX AND SPINNERET; MELTBLOWN HEAD AND SYSTEM

6. COOLING AND STRETCHING SYSTEM

7. WEB LAPPER& CONVEYOR

8. CALENDER IN HIGH TEMPERATURE AND HIGHSPEED; WINDING& SETTING&

SLITTING& CUTTING

9. WAREHOUSE FOR FABRIC STORAG

SMS

Effective Width (mm) | Raw Material | GSM Range (g/sqm) | Max Speed (m/min) | Annual Capacity (Ton / year ) | Daily Capacity ( Ton / day ) | |

| 1600mm | Polypropylene(PP) |

9-100g | 350 | 3200T | 9T | |

| 2400mm | 5100T | 14T | |

| 3200mm | 7000T | 19T | |

| 4000mm | 8700T | 24T | |

SMS/SMMS/SSMS/SSMMS Model(Filtration Material, Baby Diaper ,Medical

Products)

| Working width | Fabric | Consumption | Annual output/Year |

| 1600mm | 15-250G/㎡ | 400KW | 3200T |

| 2400mm | 15-250G/㎡ | 600KW | 5100T |

| 3200mm | 15-250G/㎡ | 800KW | 7000T |

| 4000mm | 15-250G/㎡ | 1000KW | 8700T |

| 4800mm | 15-250G/㎡ | 1200KW | 10500T |

S Model (Packaging , Agricultural Cover )

| Working width | Fabric | Consumption | Annual output/Year |

| 1600mm | 9-250G/㎡ | 130KW | 1800T |

| 2400mm | 9-250G/㎡ | 180KW | 2200T |

| 3200mm | 9-250G/㎡ | 200KW | 3300T |

| 4000mm | 9-250G/㎡ | 300KW | 4400T |

| 4800mm | 9-250G/㎡ | 400KW | 5100T |

SS Model ( Baby Diaper ,Medical Products )

| Working width | Fabric | Consumption | Annual output/Year |

| 1600mm | 9-120G/㎡ | 200KW | 3700T |

| 2400mm | 9-120G/㎡ | 2500KW | 5100T |

| 3200mm | 9-120G/㎡ | 200KW | 6600T |

| 4000mm | 9-120G/㎡ | 300KW | 8800T |

| 4800mm | 9-120G/㎡ | 450KW | 10000T |

Parts of spunbonded nonwoven fabric production line:

Recycle extrude→Main extruder→Filter→Metering pump→Monomer suction

device→spinning box( Changzhou/ENKA/KASEN spinneret )→Quenching air

chamber→stretching device→Web former→Calender→Winder→Slitter

Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)→Raw

material→Melting→Filtering→Measuring→Spinning→Cooling→Stretching→Web

forming→Calendering→Winding→Cutting→Final product

Parts of Melt blown nonwoven fabric production line:

Main extruder→filter→Metering pump→Air heating system→Melt blown

sprayer (ENKA sprayer)→Web former→Winder→Slitter

Melt blown process and technical flow chart:

Raw material →Melting→Filtering→Measureing→Air heating→Spraying→Web

forming→Winding→Cutting→Final product

Raw Material Dosing Machine

Weight system: by weight; Hopper : 4 pcs; Accuracy:0.01%; Feeding

Percentage: 1-99%; Original:USA/ITALY;

Meltblown heater

Melting injection cloth heater is an electric heating device

installed in a tube insulation container to heat gas and

liquid.Melting-blown cloth heater has fast heating speed, good

insulation performance and high heating temperature.

Spinning Beam

Model:1600/2400/3200mm; Heating System:Oil/Electricity Heating;

Distribution Design: big hanger type; Original:CHINA;

Extrusion Machine

Aperture:90 300kg/h 1pc;

Heating System: electricity heating; Drive Motor: Siemens;

Original:CHINA;

Automatic Winding Machine

Effective width:1600/2400/3200 mm Rolling Speed:200-400M/Minute

Rolling Diameter:2000 mm Original: CHINA

Production Line Control Cabinet

Voltage: 380 V/3 Phase; Touch Screen:Siemens; PLC: Siemens;

Frequency:Siemens; Indicator: RKC,JAPAN; Original:CHINA;

High precisely CNC center hold machining parts beyond customer

requirest .

Exhibition show with customer

Shipping and packing

Be Coated with anti-corrosion oil, and covered with plastic film,

then packed in wooden box.

FAQ

Q1: What's your warranty policy?

A1: The Seller will guarantee the machine for 18 months since the

date of shipment (that is leaving from Seller's factory) or the

seller will guarantee the machine for 12 months since the date of

starting installation and adjustment, whichever comes first.

Q2: What's your minimum order quantity?

A2: Min order quantity: 1 set or by negotiate with each other.

Q3: What package do you use for the product?

A3: Be Coated with anti-corrosion oil, and covered with plastic

film, then packed in wooden box.

Q4: Do you have technical instruction if I buy your product?

A4: Please read the user manual carefully for your reference, we

have detail instruction on it. If your problems still cannot be

solved, welcome to contact us for help.

Q5: What is your overseas service?

A5: We will provide high quality overseas service, our technical

staff will be able to provide you with technical support, for you

personally to overseas assembly and test equipment.

Q6: Will you conduct training for our staff here?

A6: Yes, we will provide technology support to factory technology,

training for the relative person.

Q7: What are your terms of payment?

A7: We accept T/T.

Q8: How does your factory do regarding quality control?

A8: Quality is priority. We always attach great importance to

quality controlling from the beginning. And we have CE certificate.

Q9: How does your factory control the quality?

A9: We have the professional QC group inspect the details in each

process. After finishing the goods, our QC will inspect piece by

piece.

Q10: I am very satisfied after I read your FAQ, how can I start to

purchase my order?

A10: Please click the "send" at the bottom of this page or contact

our sales on Trade Mange online!

Dear friend:

Welcome you purchase our standard products or send us your OEM and

ODM requests. You will be impressed by our superior quality, quick

delivery date and attractive price. If any question about non-woven

machine, contact me at any time, please!