Gown Material anti bacterial SMS SMMS SS SSS PP Spunbond Nonwoven

Production Line

SMS function definition:

Softness and stiffness. Fineness, scalability.

It can be filtered, breathable and waterproof. Flexibility,

rigidity.

As thin as cicada wings and as thick as felt. Water is permeable

Filling resistance, wrinkle resistance, good elasticity, high

moisture absorption and water repellency.

Spunbonded non-woven fabric: the polymer is extruded and stretched

to form continuous filaments, which are laid into a network, and

the fiber network is formed by self-adhesive, heat sealing,

chemical bonding or mechanical bonding. Method for making fiber web

into non-woven fabric.

Features: good performance (can be used at 150 ℃ for a long time,

polyester can be used at 260 ℃ for a long time), aging resistance

and,. UV, high elongation, good stability, good air permeability,

corrosion resistance and sound insulation

use

Medical and health category: surgical clothing, operating table

cloth, patient clothing, protective clothing, respirator, packaging

bag, etc.

Labor safety articles: protective clothing, automobile and motor

protective cover, dust cover, painting work clothes, etc.

Tourist supplies: beach umbrella, beach clothes, recycling bags,

etc.

Cleaning supplies: baby diapers, adult incontinence pads, sanitary

napkins, filter materials, etc.

Date bases

| Process speed | 9-320 M/MIN |

| Model | HHM-PP 1600 |

| Capacity | 6-10T / Day (calculation basd on fabric 15 gsm , width at 1600 mm) |

| Filament Denier | SPunbond :1.5~2.5D Meltblown:1.6~4um |

| Fabric weight | 10~100gsm |

Total installed Power(kw)-sms | 1299 |

Actual Power Consumption(KW) SMS | 800 |

Water Consumption(Ton/Day) | 0.3 |

| Circulation Water(m3/H) | 120 |

| Circulatin water(m3/H) | 120 |

| Raw Material | 100%polypropylene Granuyle GRade MFI 25-40 For spunbond MFI 800~1600 For Melt Blown |

Molecule uniformity Degree(%) | >98% |

| Melting Point (℃) | |

| ASH | < 0.15-0.25% |

| Plant Size | 35m*18m*12m |

| Labor Requirement | 7 Worker per shift ,2 shifts per 24 hours , totally 14 workers . |

After-sales service

Installation:

The seller will send 2 or 4 engineers to install, test the

production line and train customers’ workers in buyers’ factory. It

will take 1 month for whole installation and training.

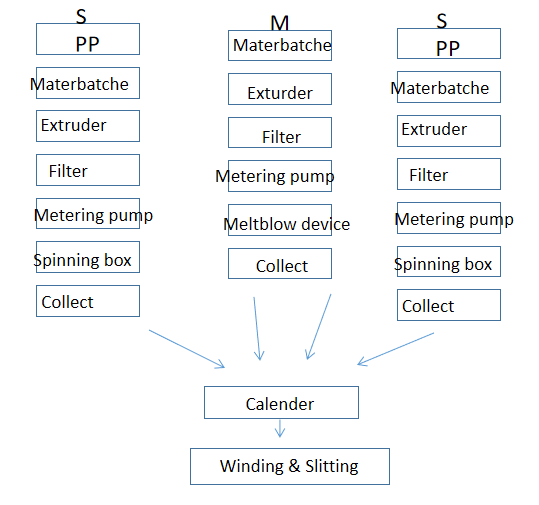

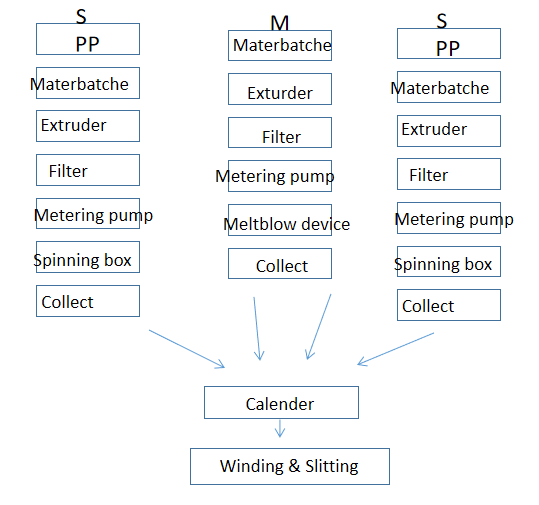

Process flow:

Parts of spunbonded nonwoven fabric production line:

Recycle extrude→Main extruder→Filter→Metering pump→Monomer suction

device→spinning box( Changzhou/ENKA/KASEN spinneret )→Quenching air

chamber→stretching device→Web former→Calender→Winder→Slitter

Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)→Raw

material→Melting→Filtering→Measuring→Spinning→Cooling→Stretching→Web

forming→Calendering→Winding→Cutting→Final product

Parts of Melt blown nonwoven fabric production line:

Main extruder→filter→Metering pump→Air heating system→Melt blown

sprayer (ENKA sprayer)→Web former→Winder→Slitter

Melt blown process and technical flow chart:

Raw material →Melting→Filtering→Measureing→Air heating→Spraying→Web

forming→Winding→Cutting→Final product

Feeding(suction,dosing and mixing) →Melt and extruding(with recycle

extruder)→Filtering→Metering→Spinning→Quenching→Airdrawing→Forming→Calendering→Winding→Slitting→Product

Installed power: 600KW

Web width: 3200mm

Max. winding diameter: ф1200mm

Annual output: 3000tons (50g/m2)

Single filament titer: ≤2.5 denier

Web weight: 10-200g/m2

Max. mechanical speed: 0-120m/min (Process speed:10-100m/min)

Electric consume: 700KWH(for 1ton product)

Workers and power

Number of workers: 3-4persons

External power supply: 500KVA

Water system: 0.2Mpa

1.Parts of spunbonded nonwoven fabric production line:

2.Spunbonded process and technical flow chart:

Parts of spunbonded nonwoven fabric production line:

Recycle extrude→Main extruder→Filter→Metering pump→Monomer suction

device→spinning box( Changzhou/ENKA/KASEN spinneret )→Quenching air

chamber→stretching device→Web former→Calender→Winder→Slitter

Spunbonded process and technical flow chart:

Additive(Recycling off-cut fabric)→Raw

material→Melting→Filtering→Measuring→Spinning→Cooling→Stretching→Web

forming→Calendering→Winding→Cutting→Final product

4, Image of our Machine line :

Advanced Equipment

Exhibition show with customer

Shipping and package

Welcome vist us

HH Nonwoven Machinery Co., Ltd. to produce and sell spunbonded

non-woven equipment, melt-blown non-woven equipment, spunbonded

non-woven, melt-blown non-woven, Non-woven Fabric related technical

support, non-woven electrical technical support and other related

business.

Product use:Protective clothing,Mask,packing bag,diaper,Adult

incontinence pad,tampon,Filter material etc.

1. Why choose us?

We are a high-tech enterprise integrating production, processing,

sales and after-sales, with a complete and scientific quality

management system.We infiltrate each other with unique creative

solutions and super technical capabilities, presenting a unique and

tailor-made solutions that perfectly suitable for you.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

Spunbond meltblown fabric making manchine line , S SS SSS SMS SMMS

SSMMS ,effective width from 1600mm to 4800 mm and non wove machine

parts , more over we also have own fabric factory can supply kinds

of fabric ,for detail pls contact us .

SMMS PP Meltblown Non Woven Fabric Making Machine Melt Blown

Nonwoven Cloth Production Equipment.