Melt blown filter polypropylene melt-blown Meltblown Nonwoven

fabric Machine

Technical Advantages

1) The whole line is well-structured and easy to operate.

2) The whole line is highly automated.

3) Control elements are of well-know make, high performance and

reliable technologies.

4) The whole line are controlled by PLC and operated with

touch-screen.

5) The allocation of the main frame and auxiliary equipment can be

special designed and adjusted according to customers requirement.

1.Nonwoven Fabric Usage:

1) Medical and health usage:operation suit,garment,face

mask,diaper,sanitary napkin,disposable hygiene product.etc;

2) Home decoration:shopping bag,wall covering fabric,table

cloth,bed sheet,bedspread.etc;

3) Lining for clothes or shoes:lining,adhesive interlining,shoe

lining.etc;

4) Agricultural usage:Protection cover,nursery cover.etc;

2.Best defender against viruses

Stable manufacturing of melt-blown nonwoven fabric plays a key role

in effectively managing the pandemic. Both the masks made for

medical personnel and for consumer purchase require a once-obscure

material called melt-blown fabric. It’s an extremely fine mesh of

synthetic polymer fibers that forms the critical inner filtration

layer of a mask. Its porous composition enables the effective

filtering of gases and liquids, as well as the absorption of

potentially harmful airborne substances, allowing the wearer to

breath while reducing the inflow of possible infectious particles.

3.Features

Dosing & metering system

Vacuum suction or blower feeding system. Gravimetric metering

system with precise accuracy. Automatic alarm for high and low

position limit.

Spinning beam

Single coat-hanger melt distribution, manufactured by 4-coordinates

CNC, grinding by manual.

Quenching chamber

Several layers multistep honey plates with different size holes.

Quenching air distribution is uniform and easier for dismounting

and cleaning.

Stretching channel

Inside wall is made of polished stainless steel, top and bottom

stretching channels can adjust slot width at the same time.

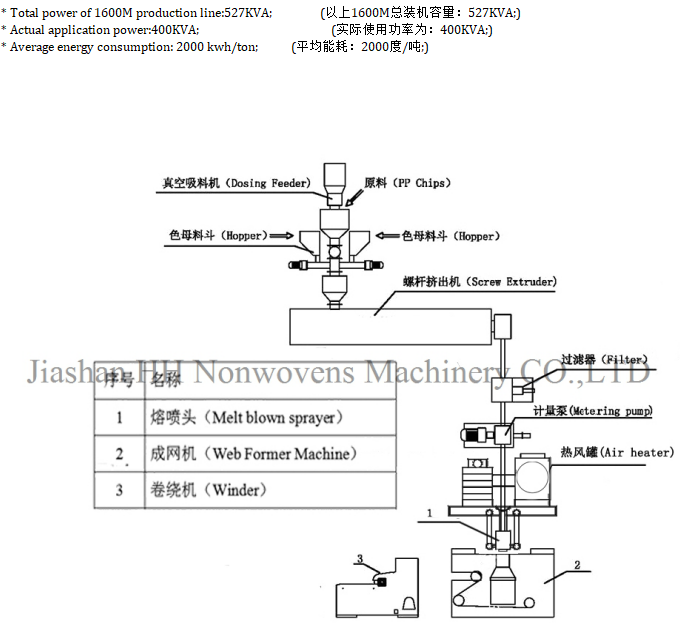

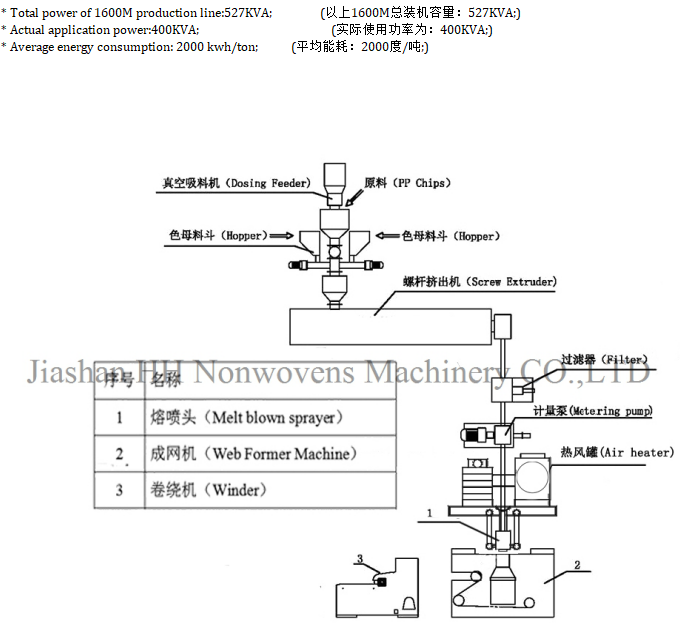

The melt-injection production line mainly includes the feeder,

screw extruder, filter device, metering pump, melt-injection mold

head assembly, Roots blower, air heater, receiving device, winding

device.Production auxiliary equipment mainly includes forging

furnace, ultrasonic cleaning furnace, etc

Technical Parameters

Description

| Raw materials | pp polypropylene | Melting point | 166℃ |

| Spunbond pp melt index | 28-45 | Denier of spunbond fiber | 1.8-2.5 denier |

| Meltblown pp melt index | 1300-1800 | Denier of melt blown fiber | 1.6-4 microns |

| Model | HHM-1.6m | HHM-2.4M | HHM-3.2M |

| Effective Width | 1.6 M | 2.4 M | 3.2 M |

| Weight Range | 18-300 G/㎡ | 18-300 G/㎡ | 18-300 G/㎡ |

| Out put day | 2-3 Ton | 3-4 Ton | 4.5-5 Ton |

| Machine Speed | ≦40 m/min | ≦40 m/min | ≦40 m/min |

| Power Consumption | 3000º-3500º/Ton | 3000º-3500º/Ton | 3000º-3500º/Ton |

| Machine Size(L*W*H) | 18M*10M*10M | 18M*11M*10M | 18M*13M*10M |

PP melt-blown nonwoven cloth machine list:

No. Machine list Qty.

1. screw extruder 1set

2. Mould 1set

3. Spinneret plate 1set

4. Air heater 1set

5. Gas tank 1set

6. Air compressor 1set

7. Frozen type compressed air drying machine 1set

8. Web Former machine 1set

9. Slitting Machine 1set

10. Winder 1set

Name:Main Extruder

Brand:HHM

Original:China

Diameter:Φ135mm for 1.6m,Φ170mm for 3.2m,

Max speed: 75r/min for 1.6m , 85r/min for 3.2m

Motor:90kw for 1.6m , 132kw for 3.2m

Fuction: Automatic heat , melt and extrude the PP materials

The role of spinneret is to transform viscous flow of polymer melt

or solution into small section with special section, and solidify

through solidified medium, such as air or solidification bath. It

is used for the uniform exit of the tow.

Name:Metering Pump

Brand:HHM

Original:China

Supply volume:200cc for 1.6m, 200ccx2 for 3.2m

Rotate speed:5~35r/min

Max Pressure:35MPa

Temperature:≤330℃

Fuction: meter PP melt liquid

Name: Material Auto-Feeder

Brand:HHM

Original:China

Feeding capacity: 500kg/h for 1.6m , 800kg/h for 3.2m

Delivering distance:12m

Material:stainless steel

Fuction: Automatic sucking the PP materils to the non woven fabric making

machine

Workflow:

PP raw material→Melting and

extrusion→filter→metering→spinning→flame spray+flame spray(mect

blow)→spinning→Net laying→Calendering→Winding,Slitting

Projet image in customer side

Our service

Pre-Sales Service

HH employees have special sense of responsibility and an excellent

team spirit,therefore machinery complies to the highest

standard in nonwoven industry creating by with individual

outstanding components. Supported by modern technology A.L designed

for

custom-built machinery and machinery offers an optimum solution for

all customer requirements.

After-Sales Service

HH supports our customers service 24 hours A day,7 days work ,Any

inquiry could be replied within 1 hour pre-sales and

after-sales. We Believe hat only :Best Quality Machine With

Innovative Ideas and Excellent After-sale Service:"shall meet your

special requirement"

parking & delivery

Machine nude packing , wooden case is optional , case packing ,

ecletric parts carton box or wooden case packaged , other machines

nue packaging wrapping with PE film keep cargo safe.

FAQ:

1. Q : Are you a factory or trading company ?

A : We are established in 2009 , has been in onwoven industry for

more than ten years .

2. Q: Do you have technical support?

A: yes , we will provide on-site installation service.

3 Q : How does your factory do regarding quality control ?

A: Quality is the most important princFAQiple . we always attach

great importane to quality controlling from the very beginnging to

the very end , our factory has passed CE and ISO certification .

4 Q :How long is you machine’s warrant period .

A : bascily one year warranty , long time service support .